Company news

A list of common faults and solutions of panel collator

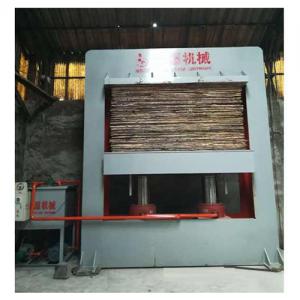

Panel collator is the most mainstream product in the platen industry, so what are the common faults and solutions of our panel collator? Our factory will tell you today.

I. plate distortion:

Due to insufficient air pressure, we need to check and repair the pipeline in time to ensure our normal production.

The uneven plate may be due to the problem of raw materials. We need to replace the plate and repair the poor plate reasonably.

The adhesive mixes with foreign material, causing the platen to twist. We need to keep the board and adhesive clean.

II. Loose splicing:

The tightening force is weak. We need to adjust the parameters of the panel splicer and increase the strength.

In this case, the plate can only be replaced to continue production.

The edge of the plate may be warped or bent, resulting in uneven force application point, which can not be compacted.

III. panel clamp damaged:

In case of problems in lubrication, we need to conduct regular lubrication inspection, increase lubricating oil in time and ensure normal production.

Whether the pressure or the tightening force is too large, resulting in damage to the panel clamp, so we need to adjust the parameters appropriately to reduce the application of force.

The pressure head fixing screw of panel clamp is loose, which is also a common problem. We can replace or tighten it.

Related news

- How much does a wooden bar stacker cost 2024-05-14

- What to do if the suction force of the w 2024-05-07

- Precautions for daily operation of the s 2024-04-30

- Maintenance work before using the splici 2024-04-23

- Is thin wood veneer suitable for using a 2024-04-16

Navigation column

Contact us

Name:Mr. XU

Tel:13563979777

Company:Linyi Senyuan Wood Machinery Co., Ltd.

Add:Machinery Industrial Park of Feixian Economic Development Zone (intersection of Xingda road and Xuyou Road)